Racking Inspections

Ensure your racking is compliant with health & safety legislation with regular pallet racking inspections from our racking inspectors.

What is a racking inspection?

Under the Provision and Use of Work Equipment Regulations 1998 (PUWER), pallet racking is classed as work equipment and is therefore subject to inspection. Said assessment is the warehouse racking inspection, an HSE racking legislative review that must form part of your risk assessment and happen annually at a minimum. Marked on a traffic light system, our Rack Inspectors carry out the racking inspections look at each racking element to determine a ranking against them of Red – high risk, Amber – medium risk and Green – low risk, respectively.

How To Increase Your Warehouse Storage Capacity

Optimising your warehouse is vital to your bottom line. See how you can improve workflow and maximise space optimisation in your warehouse.

Equipment for assessment:

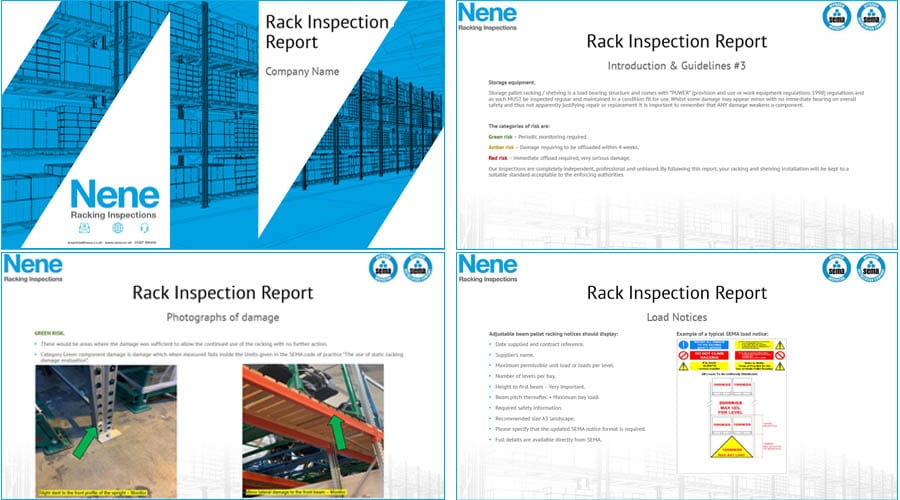

The racking inspector will work through their racking inspection checklist, looking for damage, twisting, missing items, over-loading and other factors that negatively impact the racking functionality and safety. They will work with your appointed Person Responsible for Rack Safety (PRRS), which you must have in situ as per SEMA and HSG76 guidelines. Once completed, you will receive a full, highly detailed copy of the inspection for your records. For more information, view our racking inspection checklist.

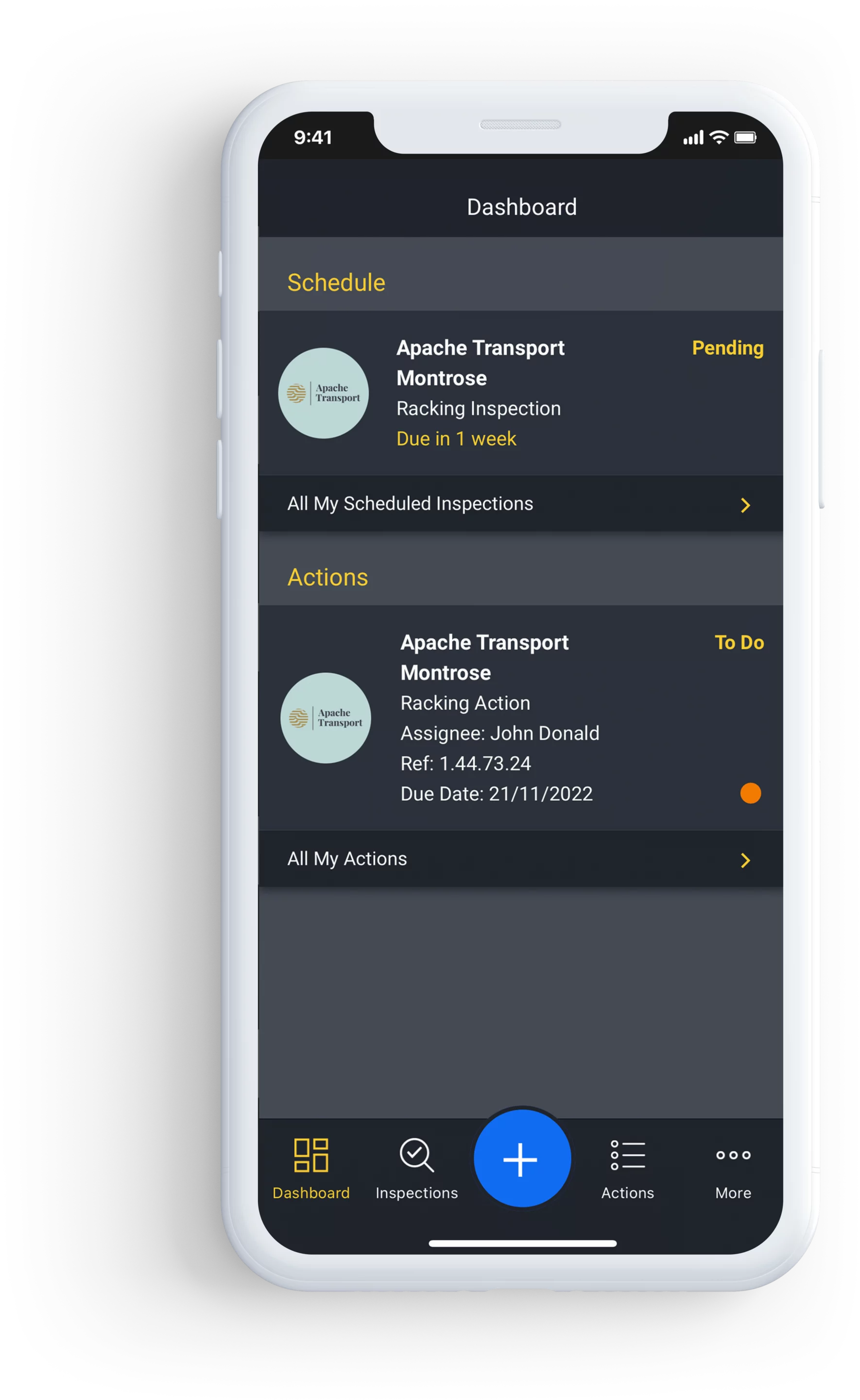

Utilising Industry-Leading Software

At Nene Warehouse Solutions, we believe in combining our expertise with the best tools available to deliver top-tier service. To ensure our racking inspections are thorough, accurate, and compliant with industry standards, we use Econform’s Racking Inspection Software.

Econform’s state-of-the-art software allows us to perform detailed inspections, capturing all necessary data with precision. This robust tool aids in identifying potential risks, ensuring that your warehouse maintains a high level of safety and operational efficiency.

By integrating Econform’s software into our inspection process, we can provide comprehensive reports that not only highlight areas of concern but also suggest practical solutions for improvement. This technological edge enhances our service, aligning with our commitment to provide you with efficient, reliable, and high-quality warehouse solutions.

Pre-loaded Manufacturer Location-Specific Information.

Econform’s software comes pre-loaded with specific information related to your racking’s manufacturer and location. This feature enables us to conduct inspections with an enhanced level of detail and accuracy, accounting for any unique specifications or requirements that your racking system may have.

Instant Bill of Materials.

Upon the completion of an inspection, Econform’s software automatically generates a bill of materials. This feature allows decision-makers to promptly obtain quotes for any necessary remedial work, significantly speeding up the process of addressing identified issues.

Sign Off on Completed Repairs.

Econform’s software also allows for locations to be signed off as soon as remedial work is completed. This feature ensures that your warehouse operations can resume with minimal downtime, maintaining the efficiency and productivity of your business.

Through the combination of Nene’s expertise and Econform’s innovative software, we are committed to providing a service that is not only thorough and accurate but also efficient and tailored to your specific needs.

Find out more about Econform.

Why do you need a racking inspection?

Firstly, it’s a legislative requirement of the HSE racking inspection guidelines to ensure compliance with health and safety regulations and measures. Your employee safety is front and centre of the inspection. Secondly, you must have a SARI inspection sign-off insurance, this will keep your premiums down and also reduce the likelihood of legal challenges.

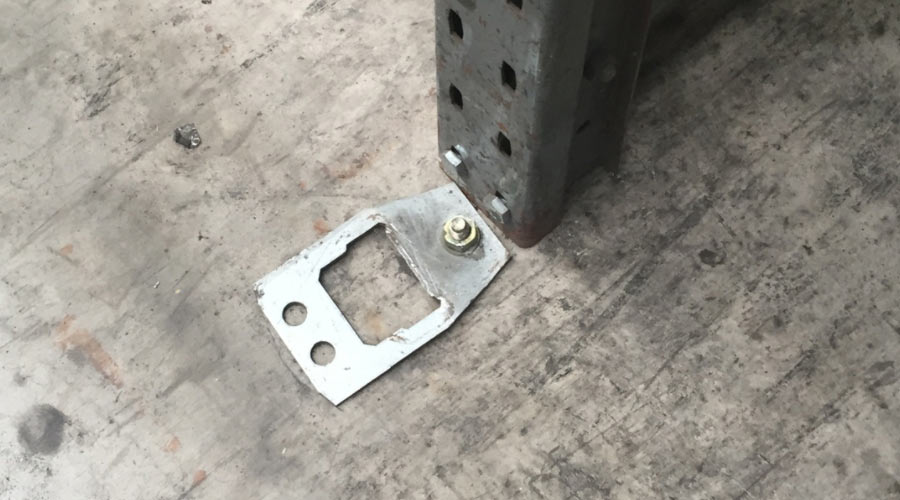

Regular inspections also positively impact maintenance costs and time, highlighting issues before becoming a Red-high risk, giving you ample time and information to rectify them.

Even newly fitted racking must have an inspection before sign-off. Find out more about why you need a racking inspection.

How do you book a racking inspection?

Nene has a UK-wide network of SARI inspectors working with their teams of installers. We provide a 360 service with add-ons available in racking and warehouse design, supply, racking installation, racking maintenance and inspection to ensure our clients’ racking meets and exceeds industry standards – providing a safe and productive environment for their staff within which to work.

You can book yours today with Nene. We will discuss all your requirements and arrange any pre-cursory meetings where required. Simply fill in the form below

Racking Inspections Brochure

Download our brochure for more information on warehouse racking inspection carried out by one of our Racking Inspectors

FAQs

Inspections

Our inspector will then walk the site thoroughly investigating the racking and making note of any damage and general housekeeping. Before leaving site, the inspector will make the PRRS aware of any concerns that need to be addressed ASAP and will ensure they are complete before leaving.

Once the inspection is complete, our inspector will complete the report and send to the Person Responsible for Rack Safety within 1-2 days.

Find out more about our racking inspections.

Please do give us a call and we can discuss your options with you.

Contact us for more information.

Any damage that occurs should be identified when it occurs, the rack unloaded, and the damage remedied.

Find out more about our racking inspections.

Though the term “recommendation” may not seem as strong a term as “requirement,” don’t let that fool you into thinking you’re less at risk if you’re found not to follow them.

If someone is injured due to poor racking safety, a claimant could prove that the warehouse didn’t follow HSE recommendations and, if convinced, you could be held legally responsible. These recommendations have to be followed to a degree that’s considered “reasonably practicable”.

Find out more about our warehouse racking inspections.

Taken from ‘Warehousing and storage, A guide to health and safety’ produced by HSE ‘to ensure that a racking installation continues to be serviceable and safe, the storage equipment should be inspected on a regular basis.

The frequency of inspections depends on a variety of factors that are particular to the site concerned and should be determined by a nominated PRRS (Person Responsible for Racking Safety) to suit the operating conditions of the warehouse. This will take into account the frequency and method of operation together with the dimensions of the warehouse, the equipment used and personnel involved, all of which could damage the structure.

Find out more about why you need a SEMA racking inspection.