Warehouse Pallet Racking

Adjustable Pallet Racking is the most versatile warehouse heavy duty racking system available, easily configurable to suit any business’ storage needs.

Versatile and popular, Adjustable Pallet Racking is a fundamental solution for most warehouses and Distribution Centres worldwide for large or homogenous goods storage and distribution.

What is Adjustable Pallet Racking?

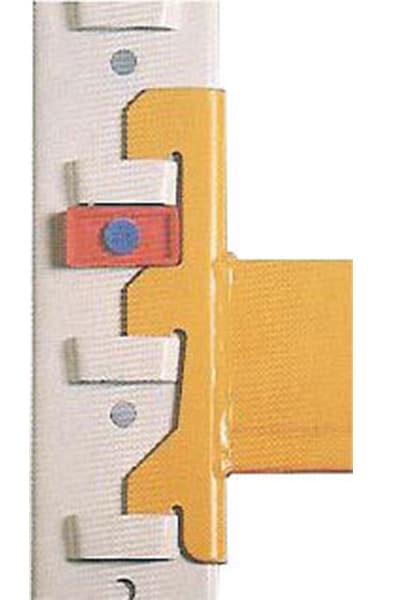

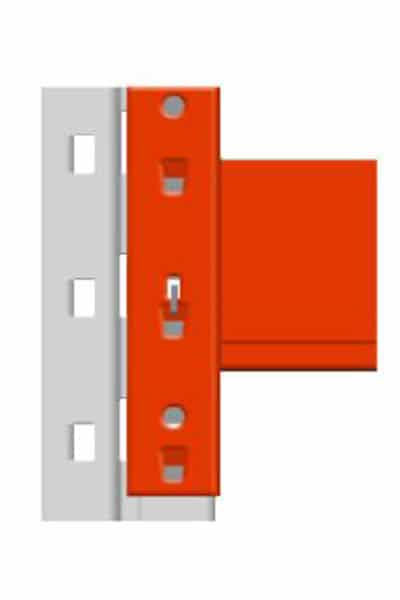

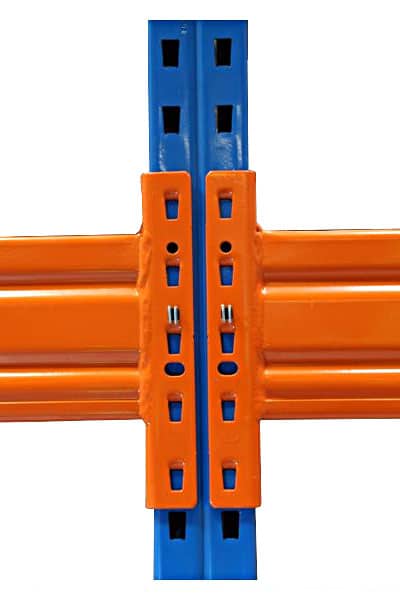

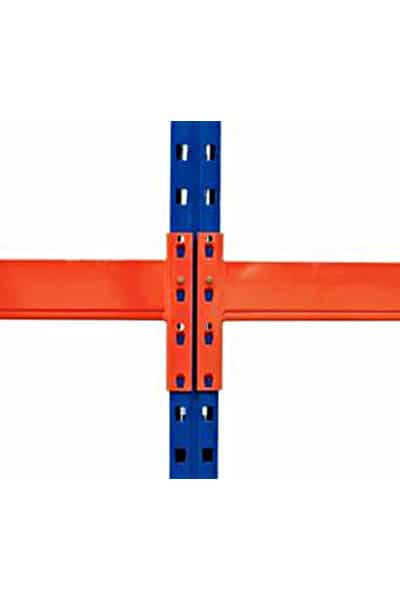

These industrial racking systems are made of industrial-grade steel comprised of upright frames, beams and connectors, Adjustable Racking forms to create a sturdy, durable and easily managed structure to house multiple pallets for goods storage.

Suitable for 2 and 4 point entry pallets, the racking is typically used with wooden pallets, picked and manoeuvred by forklifts.

Warehouse racking, how to increase your warehouse storage capacity

Need to store more pallets and products? Read on to find out what you need to be doing and considering, from type of racking, to warehouse design and more…

Adjustable Racking Configurations To Suit Your Business Needs

No matter how diverse your storage needs, Nene can provide the perfect adjustable racking systems to suit your business. Let our experts take care of it.

Wide Aisle Pallet Racking

The most widely used variant of Adjustable Racking, each pallet within Wide Aisle Pallet Racking is independently supported and accessible. Typically, the aisle is of a minimum 2.5m width, and so standard forklifts can be used, and it requires no other specialist handling equipment to function.

There is a limitation on height, depending on the truck’s reach capabilities, but that doesn’t stop Wide Aisle from being a prevalent choice in warehouse design. Easily configured to suit various spaces, its intelligent, durable, yet straightforward design makes it a firm favourite.

Very Narrow Aisle Pallet Racking

Ideal when space is limited, our Very Narrow Aisle solutions provide full accessibility to goods stored in high density, compacted into a small space. Designers can increase the warehouse capacity without any need for building or expansion works by utilising narrower aisles.

Specialist handling equipment is required to accommodate the pick’s height with the narrow width of the aisle. Narrow aisle forklift trucks, known as trilateral or bilateral turret trucks, are trucks for working in narrow aisles – a combi VNA truck is ideal.

Very Narrow Aisle Racking is hugely flexible, intelligent and straightforward like its Wide Aisle counterpart, allowing multiple variables in design and type of stock held while optimising the space to its desired capacity.

Mobile Pallet Racking

For increased stock density when space is at a premium, conventional pallet racking are mounted on fully manoeuvrable bases, made mobile with tracks set into the floor.

This system allows for same-day reconfiguration, either manually or by remote software. If you have goods coming in that need to be stored in a certain way, temperature, for example, or you are not aware of their condition before they arrive, this is an ideal way to react quickly and have complete accessibility to the goods in situ.

Mobile Racking Systems can increase your storage capacity by as much as 90% thanks to its flexibility and positively impact your warehouse running costs as a result too.

Drive-In Pallet Racking

Modular in structure and typically for high-density items, Drive-In Racking is the most popular solution for storing homogenous products of the same SKU on a large number of pallets.

With Drive-In and Drive-Through, the access routes are minimised in favour of capacity. The first pallet in is the first one out, and so working this way and limiting the number of access points, in this instance, helps increase warehouse capacity. It is a compact system that works well where space utilisation is paramount, and the pick is simple.

Live Racking

Live Storage racking works on a FIFO (First In, First Out) and LIFO warehouse management (Last in, First Out) basis, using gravity, push-back or carton-flow systems to fulfil the space created by the picked item. The need for fewer aisles means there is more capacity for stock, fewer human resources are required, making it safer, and load and pick times are significantly reduced. Live Racking is an ideal solution when stock control and rotation are paramount.

Push Back Pallet Racking

Explicitly designed for LIFO goods management, Push Back Racking systems are fitted with rollers on the racking or shutters on each pallet base to make them mobile. A high-density storage system, load and pick are conducted at the front, pushing the existing stock further back into the racking.

An excellent space optimiser, Push-Back Racking is perfect for those looking to maximise the space they have with few SKU variants to consider. It can also be integrated with other systems and so is ideal for multi-product facilities.

Our Adjustable Pallet Racking Range

We supply and stock all of the major industry leaders in racking manufacturing, it’s hard to find a manufacturer that we don’t do.

At Nene, we have a comprehensive range of Adjustable Racking solutions available to allow you to maximise your storage. Implementing Adjustable Racking will enable you to take full advantage of the height, width and depth of the space available in your facility, optimising your warehouse to its full potential.

Our complete design-and-build service delivers market-leading equipment and functionality, using top manufacturers and skilled designers to make our clients’ specific pallet racking concepts a working reality.

Adjustable Racking Health and Safety

As with any industrial equipment, health and safety measures and protocol are critical to your employee’s well-being and productivity and can also impact the conditions in which the goods are stored. Regular rack inspections will ensure you are insured correctly, working to industry regulation standards, protecting your employees by providing a safe environment and ensuring you are covered should an incident occur. Our fully qualified SEMA inspectors are available for inspection to cover the annual minimum and can be called in ad-hoc to inspect more frequently where appropriate, especially in high-turnover facilities.

At Nene, we provide maintenance service agreements to ensure your equipment is kept in prime condition and help spot any damage, wear, or tear before it escalates to full health and safety issues. Prevention is the best course of action to protect your people, your premises and pass your inspection.

Get in touch with the Nene Warehouse Solutions Team

Speak to our racking experts to discuss your project, simply fill in the form below.

Racking Solutions Brochure

Download our brochure for more information on our racking solutions.

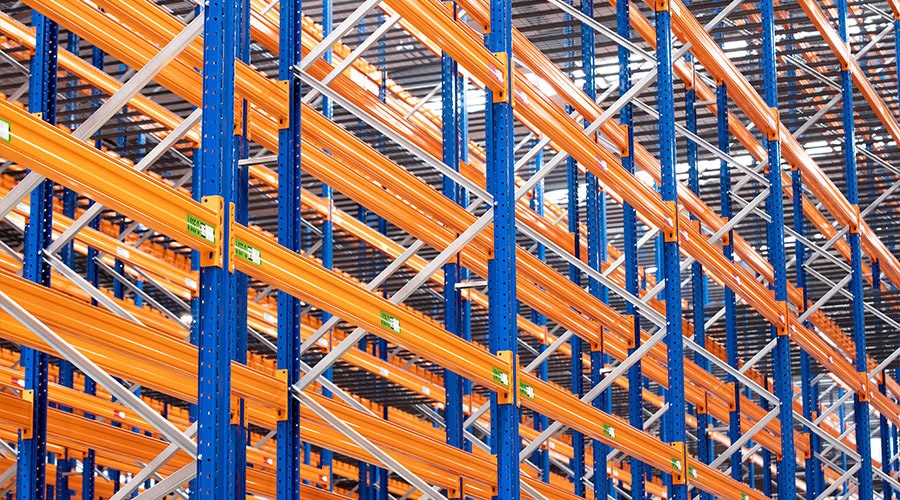

Adjustable Racking Gallery

FAQs

Inspections

Any damage that occurs should be identified when it occurs, the rack unloaded, and the damage remedied.

Find out more about our racking inspections.

Outdoors

Utilising outdoor space can be a great way to increase the amount of storage capacity you have. It can also give customers direct access to products they can pick themselves.

A typical racking system for outdoor use is cantilever racking.

Racking

We have a brand-new system called Gondola Skate. Our innovative product can mobilise and move shelving units of any type in 20 minutes, without the need to de-merchandise or empty shelves of stock.

Take a look at our video to see it in action.

Find out more about our warehouse racking mobilisation.

This gives us the opportunity to get a good look at the site and discuss all your business needs so we can design the right solution for you.

We have worked with every industry you can imagine, and they all have special and unique requirements.

Take a look at our case studies for some examples of what we are capable of..

It is a flexible and versatile way of getting the racking you need for your business. Hire periods run for anything from four week to five years.

Design install and ongoing racking maintenance are all included in the monthly cost making it a fantastic all-inclusive option.

Find out more about our racking hire.

This gives us the opportunity to get a good look at the site and discuss all your business needs so we can design the right solution for you.

Just take a quick look at our what racking do I have? page to identify your racking system.

If you are still stuck please do give us a call.

With over 40 years’ experience, dedicated project managers, and a huge centrally located stock holding we are true experts in our field and can guide you through every step of the process to get the right storage solution for you.

We are SEMA accredited and put safety at the forefront of all we do.

Contact us today for a free site visit to discuss your needs.

With over 40-years’ experience, we can help you determine the best system for you and guide you through every step of the process.

We offer a free no-obligation site visit where one of our team will come to you, complete a full site survey and chat through your requirements.

We have worked in a wide variety of sectors and will be able to help you make the best choices for your business.

Contact us for more information.